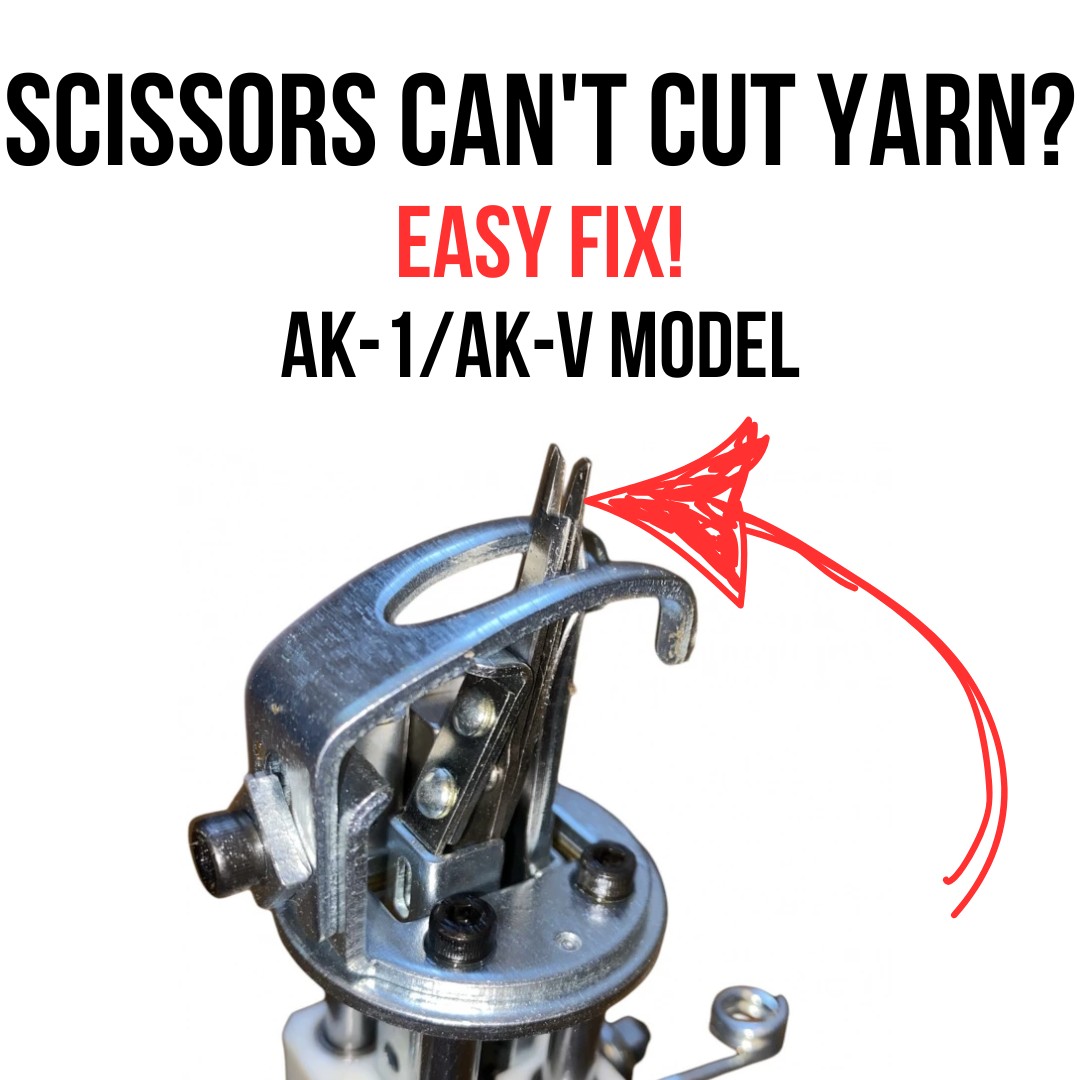

Is your tufting gun scissors no longer cutting tufting yarn? Or perhaps your tufting gun doesn’t cut yarn as it should? These issues can occur for various reasons, such as modifications, accidental drops, or misalignments in the scissors mechanism. In this article, we’ll provide a step-by-step guide to diagnosing and resolving problems with the tufting scissors on your tufting gun. We’ll also include a detailed video tutorial to help you visually follow the process and get your tufting gun back to perfect working order. Step-by-Step Guide to Fixing Tufting Gun Scissors Step 1: Test the Scissors Mechanism Before making any adjustments, ensure that the tufting gun scissors are functioning correctly. Here’s how: Manually inspect the...

Tufting gun - 2 in 1 Cut and Loop (AK-1) documentation

The Tufting Gun 2-1 Cut and Loop (AK-1) is a versatile tool for creating intricate designs with both cut and loop pile techniques. Our documentation provides guidance on how to maximize the performance of this powerful device, ensuring precision and efficiency in your tufting projects. Learn about proper maintenance procedures to prolong the lifespan of your AK-1 and troubleshooting tips to address common issues.

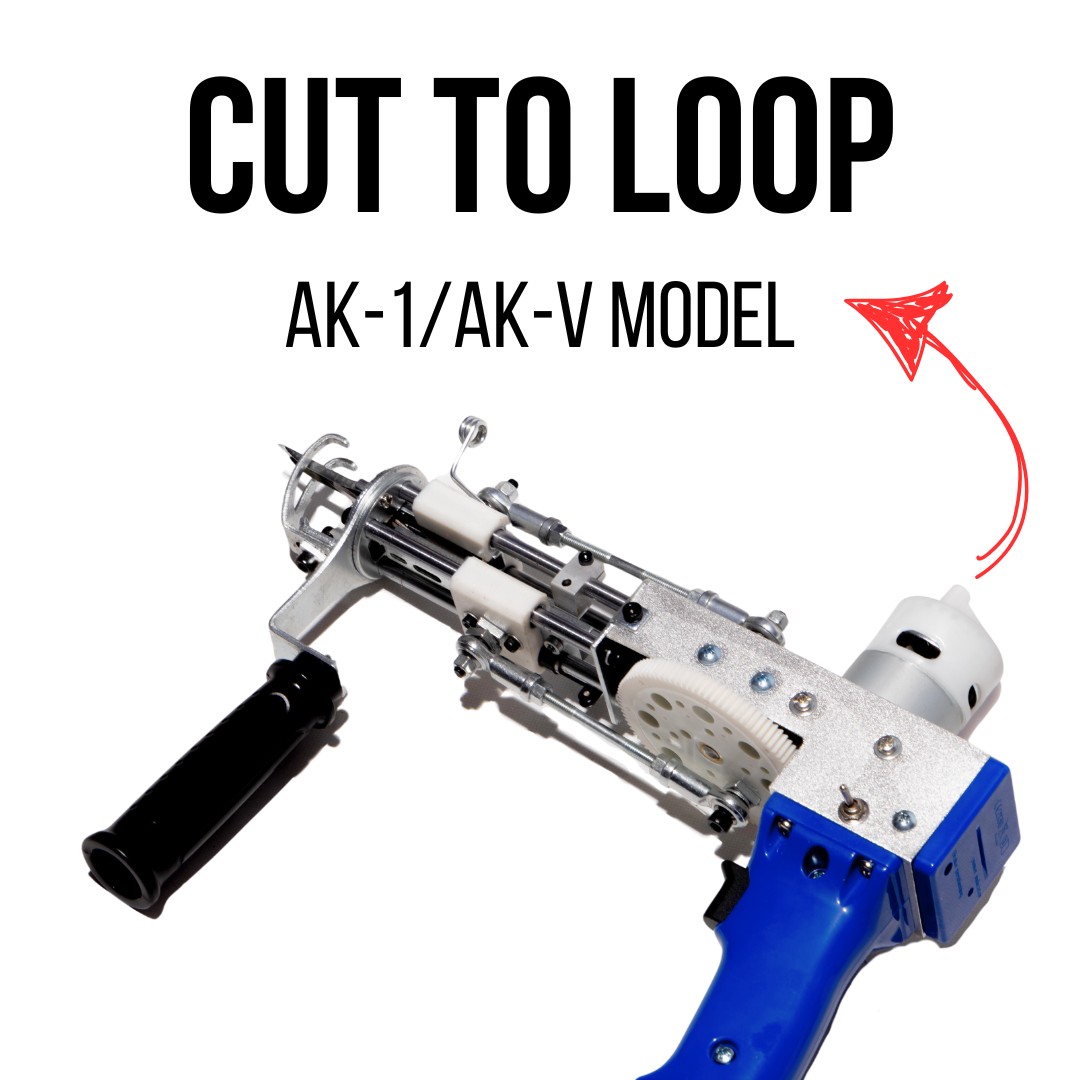

Switching between cut pile and loop pile might sound challenging, but it’s a simple process that takes just a few adjustments. This guide applies to the Tufting Gun (AK-1) – 2 in 1 Cut and Loop and Tufting Gun (AK-V) – Cut and Loop models. For those who focus primarily on loop pile, the specialized Tufting Gun (AK-2) – Loop is an excellent option, providing high-quality loops without the need for adjustments. Before making any changes, always remember: safety first. Disconnect your tufting gun from electricity before starting any adjustments. Step-by-Step Guide to Switching Modes Unplug the tufting gun. Disconnect your tufting gun from electricity to ensure safety. Locate the adjustment screw. On the right-hand side n...

What Oil Should You Use on Your Tufting Gun? When it comes to maintaining your tufting gun, proper lubrication is crucial for smooth operation and to prevent overheating. Here’s a straightforward guide on choosing and applying the right oil. Best Oils for Your Tufting Gun: Sewing Machine Oil: This is the top recommendation due to its light viscosity and ability to keep your machine running smoothly without leaving residue. One of the most premium sewing oils is our Eurol® Oil. WD40: Cheap options that basically makes the work done, but sewing machine oil is better for regular maintenance because it’s specifically designed for mechanisms like those in tufting guns. Both options are correct choices for oiling a tufting gun. Addi...

By following these maintenance guidelines, you can ensure that your tufting gun remains in optimal condition, delivering high-quality tufts consistently. Proper care and attention will extend the life of your equipment, allowing you to create beautiful rugs and carpets for years to come. Tufting gun maintenance is dived into 3 important sections to follow. Basic Maintenance Proper maintenance of your tufting gun is crucial for its longevity and optimal performance. Here are some fundamental st...